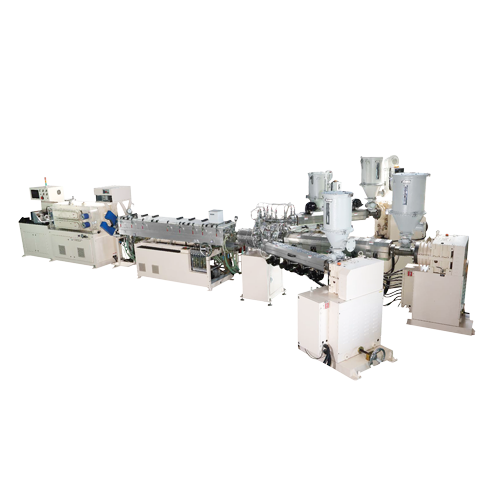

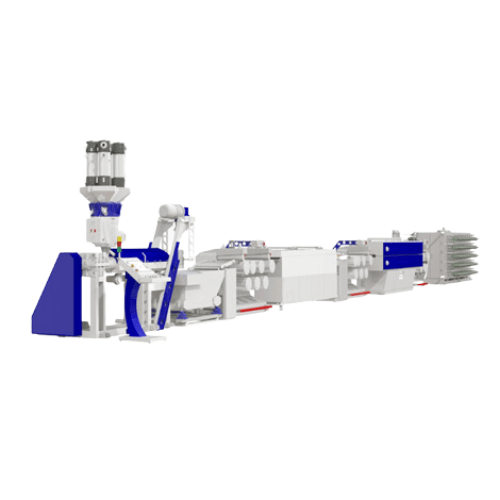

RePET Wood WPC Co-Extruder

Categories : Extrusion Lines For Pipes and Profiles

RePET Wood WPC Co-Extruder Single screw

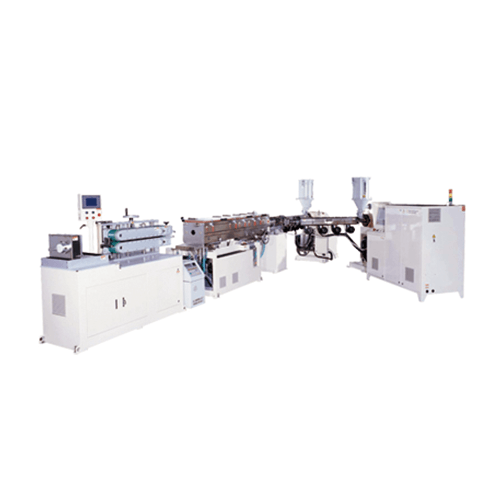

Co-Extruder, Co Extrusion Machine

Categories : Extrusion Lines For Pipes and Profiles

Part for indoor and outdoor application: Door Frames, Furniture Components, Spacing Panels, etc.

Single Layer Blown Film Extruder

Categories : Blown Film Extruder Parts

Single Layer Extruder is a commonly used type which HSIN LONG has rich manufacturing experiences. It is available for customers to choose the suitable collocation of components to meet their requirements. In addition, it allows to add recycled materials for saving the cost. There is a wide range of the application for HDPE and LDPE film products which applied with this Die Head in our daily life. Despite there are lots of advantages in other types of Die Head, Single Layer Extruder is still a great choice for use of many applications.

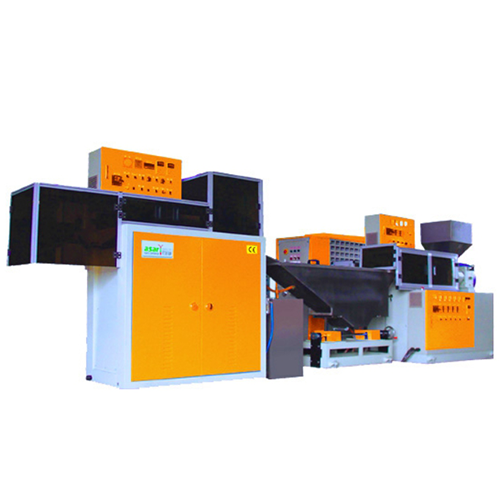

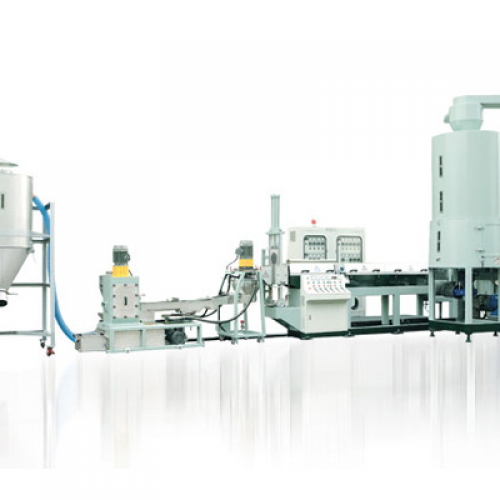

Feeder-Ruder Pellet Making Extruder

Categories : Feeders

Extrusion & Pelletizing for Rubber、Plastic & Chemical Industries This new model Feeder-Ruder Pellet Making Extruder usage for extruding and pellet making after Plastic or Rubber compound mixing in the Dispersion Kneader and conveying to the hopper of this machine. Pellets making method with mold Hot Face Cutting and Water ring cutting two kind.

Tandem Extruder Machine (YSJ)

Categories : Extrusion Coating Machines

● Working Material: BOPP film, CPP film, PET film, Cellophane, Aluminum foil, Paper, Non-woven fabric, PE film, Nylon film ● Resin: PP / LDPE / LLDPE / EVA / EAA / SURLYN

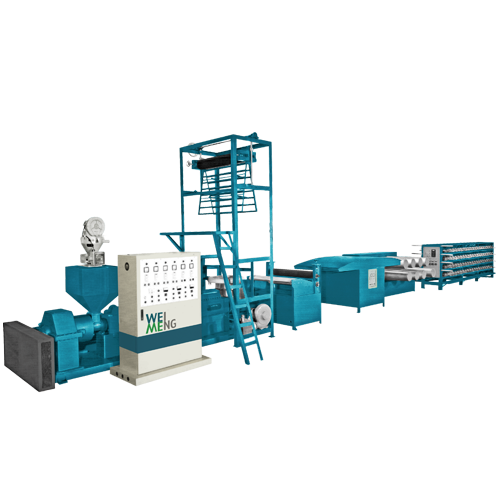

Flat Yarn Making Machine

Categories : Extrusion Lines For Filaments and Yarn

Wei Meng Industrial Co., Ltd. is specialized in manufacturing flat yarn making machine for many years. Based on continuously research and development foundation, the latest models have been launched irregularly. Until now, in our flat yarn making machine, we offer many models such as JO-85, JO-100, etc. Besides, we provide a cheaper price and superior service to all customers. Please click the online category, and you will get more detailed product feature and specification of flat yarn making machine.

PP & PE Flat Yarn Making Machine Whole Plant Project for Cement / Woven Bag

Categories : Extrusion Lines For Filaments and Yarn

K.S. became a worldwide company; have achieved ISO 9002 certificate's requirements. K.S. machinery conforms to CE standard. Moreover, every machine must pass K.S. strict and careful quality control system, and pass test running before shipping out to the customer.

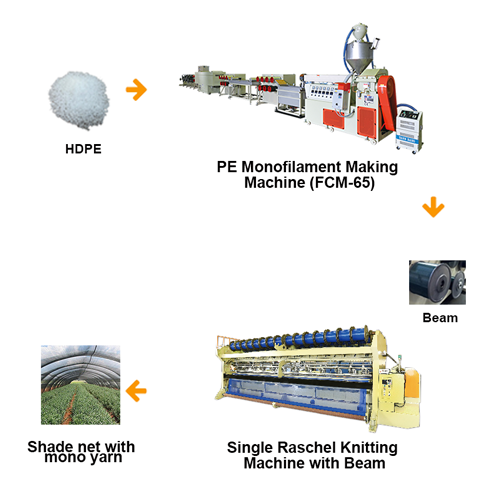

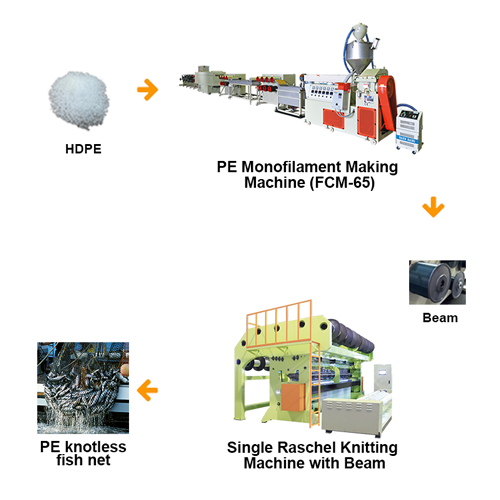

PE Knotless Fish Net

Categories : Industrial Knitting Machines

Raschel Knitting Net, PE Knotless Fish Net

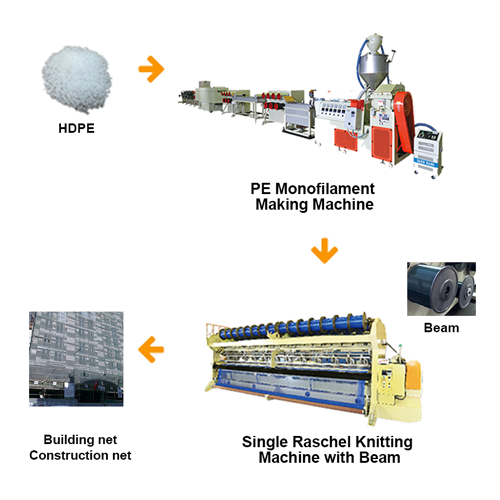

Building / Construction Net

Categories : Industrial Knitting Machines

This extrusion line is designed for making monofilament and suites for PE raw material. It can offer the round yarn (monofilament) to model SR-R & DR-R knitting machine. Model SR-R series is Single needle bed Raschel knitting machine which design for making the Round yarn (mono yarn) in all different kind of raw material, for example Nylon, PE, PP etc.

PE Monofilament Making Machine FCM-65

Categories : Industrial Knitting Machines

FCM-65 is the monofilament making machine with beam type winder which suites for HDPE raw material. It is suitable for our model SR-R, SR-RF & DR-R knitting machine. The winder is direct beam type so it doesn’t need to use the warping machine. Customer can save a working process of warping and also save the plant space.

Nylon Monofilament Making Machine

Categories : Extrusion Lines For Filaments and Yarn

K.S. became a worldwide company; have achieved ISO 9002 certificate's requirements. K.S. machinery conforms to CE standard. Moreover, every machine must pass K.S. strict and careful quality control system, and pass test running before shipping out to the customer.

PE & PP Monofilament Making Machine

Categories : Extrusion Lines For Filaments and Yarn

KS – MF100SC PE & PP MONOFILAMENT MAKING MACHINE WITH COMPUTER CONTROL SYSTEM

Polyester Zipper Monofilment Making Machine

Categories : Extrusion Lines For Filaments and Yarn

K.S. became a worldwide company; have achieved ISO 9002 certificate's requirements. K.S. machinery conforms to CE standard. Moreover, every machine must pass K.S. strict and careful quality control system, and pass test running before shipping out to the customer.

Monofilament Making Machine

Categories : Extrusion Lines For Filaments and Yarn

According to the processing purpose of monofilament, there are two types, one is two stages type (Equipped with stretching and annealing devices, the other is one stage type (Equipped with annealing device only).

High-Speed Zipper Profile Extruder INLL

Categories : Co-Extrusion Blown Film Machines

Zipper profile extrusion - Profile extruded by extruder directly into cooling water tank for formation. Profiles are closed and collected by carton or optional winder.

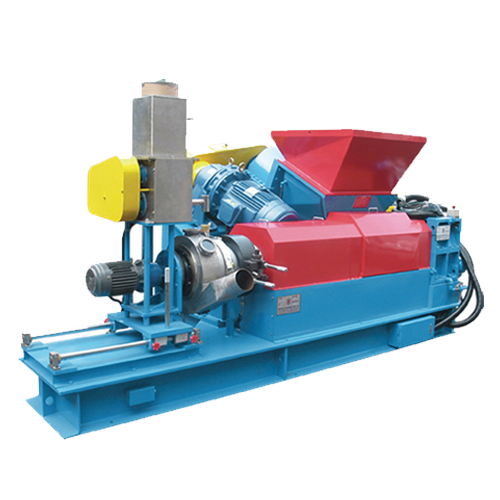

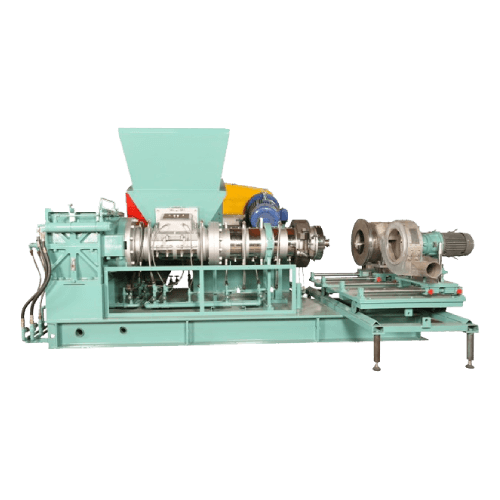

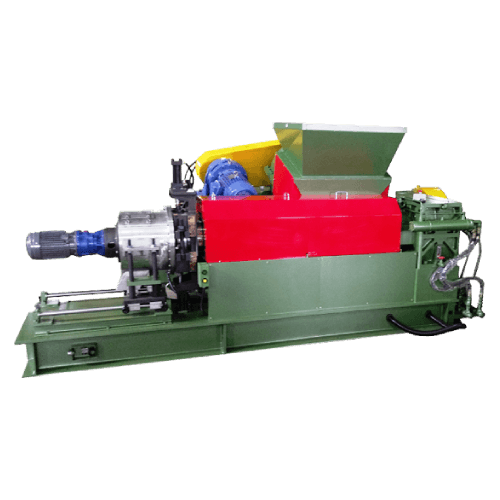

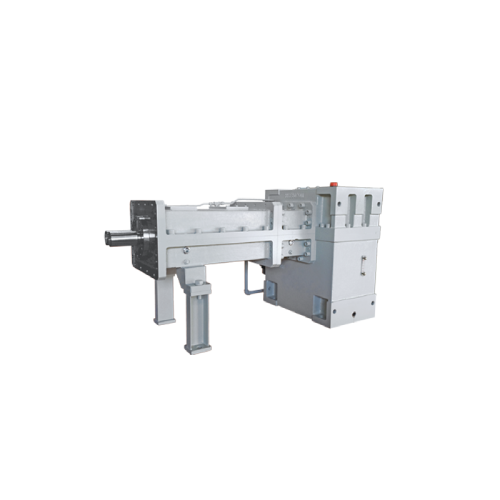

Feeder-Ruder Pellet Making Extruder

Categories : Feeders

This new model Feeder-Ruder Pellet Extruder usage for extruding and pellet producing after Plastic or Rubber compound mixing in the Dispersion Kneader and conveying to the hopper of this machine. Pellets making method with mold Hot Face Cutting and Water ring cutting two kind..

Feeder-Ruder Pellet Making Extruder

Categories : Feeders

This new model Feeder-Ruder Pellet Making Extruder usage for extruding and pellet making after Plastic or Rubber compound mixing in the Dispersion Kneader and conveying to the hopper of this machine. Pellets making method with mold Hot Face Cutting and Water ring cutting two kind.

High Speed Multi-layer PE Tube Extruder and Cutting Machine EDC-16-05

Categories : Cutting Machines

-High speed & high output -High precision thickness control on each layer of tube -Simplified control -Quick tooling change by one operator -Closed loop cooling water circulation system -Caterpillar haul-off -Automatic outer diameter control unit (optional) -Low power consumption and high production efficiency

Two-Layer PE Tube Extruder & Cutting Machine EDC-08-02

Categories : Cutting Machines

-Two-layer extrusion tube can reduce material cost. (using: Pearl + PE/PE + Pigment) -The temperature controllers of different materials can be controlled individually. In this way, we can find out the best running condition on the materials both in running fluency and dissolubility. -The surface of co-extrusion tubes made by two-layer machine is more glossy than the surface of mono-layer tubes. -Using the same material on two-layer same material on two-layer co-extrusion can increase the water-resistance and anti-penetration of the materials for about 20~30%. (using: PE + Pigment. inner: recycled material.)

Twin Screw Parallel Counter-rotating Extruder

Categories : Twin Screw Extruders

•High specific output •Outstanding melt homogeneity •Maintenance-free, closed screw temperature control system •Wide processing range thanks to metering and stuffing device •Low wear thanks to low screw speed •Gentle politicizing thanks to longer screw and barrel Applications: - Hose - Pipe

Triple Extruder Machine (YSJ)

Categories : Extrusion Lamination Machines

● Working Material: BOPP film, CPP film, PET film, Cellophane, Aluminum foil, Paper, Non-woven fabric, PE film, Nylon film ● Resin: PP / LDPE / LLDPE / EVA / EAA / SURLYN

Mono-Layer PE Tube Extruder & Cutting Machine EDC-08-01

Categories : Cutting Machines

Extrusion is the first process of making PE tubes. This process ensures glossy surface, even thickness and well-balanced composition of plastic materials. For years of research and development, our remarkable achievements on LLDPE & LDPE melting, screw design, device of die head, material adoption, and surface treatment, together with size control by figuration and length restraint by encoder have produced valuable and high-quality tubes.

Twin Taper Screw Roller Head Extruder

Categories : Rubber Extrusion Lines

MACHINE FUNCTION: The Twin Taper Screws Roller Head Extruder consists of two tapered screws and two rollers,The machine is normally applied for processing to a dispersion kneader or an intensive mixer. The rubber material,mixed by a dispersion kneader or an intensive mixer,is then fed to the rollers through the two tapered screws.It calenders the material to a desired sheet form at a constant speed. The machine is designed and engineered for high speed sheet forming operations

Multi-Layer High Speed Co-Extrusion Zipper Profile Extruder ( AB45AZ)

Categories : Co-Extrusion Blown Film Machines

MULTI-LAYER HIGH SPEED CO-EXTRUSION ZIPPER PROFILE EXTRUDER

ABA Blown Film Extruders

Categories : Blown Film Extruder Parts

The main characteristics of these kind of Extruder is available to use two or more materials to manufacture film. HSIN LONG supply customized machine specifications for different output, material, film width, film thickness. Further, it reduces the waste of material cost since it allows to add CaCo3, recycled material and color masterbatch in the middle layer for different using.

High Speed Zipper Profile Extruder( AB-40Z)

Categories : Plastic Bag Making Machines

HIGH SPEED ZIPPER PROFILE EXTRUDER

Co-Extrusion Blown Film Extruders

Categories : Extrusion Dies / Dies Heads

HSIN LONG’s Co-Extrusion Extruder is customized which depends on characteristics of raw materials and final applications. Since there are kinds of materials will be extruded at the same time, the flow channel with special design helps polymers to flow smoothly without any residue. As the need of marketing trends and the transformation in blown film industry, it is available to use recycled and colored material for more functional use.

Pellet Extruding Machines Screws / Barrels

Categories : Screws and Barrels

As leading company of Screws and barrels in Taiwan, Nan Yun is able to provide the highest quality screw and barrel for Extruder Machine. We are continually researching new screw and barrel materials that would best fit the needs for pellet extruder or plastic pelletizing machine, which results in better mixing, and critical melt quality. Nan Yun's engineers work with our customers to provide the best possible extruder screw design for extruder machine such as PVC pelletizing machine, PE pelletizing equipment, Plastic pellet extruder.

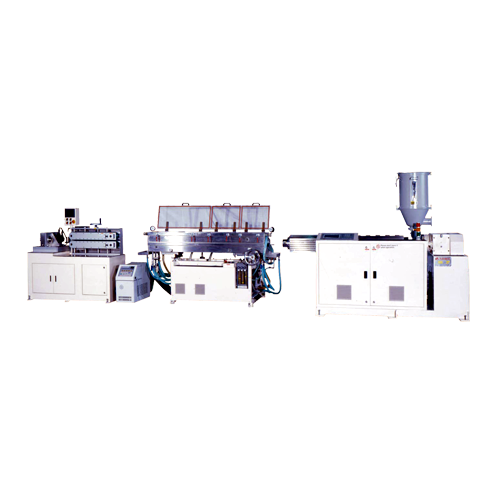

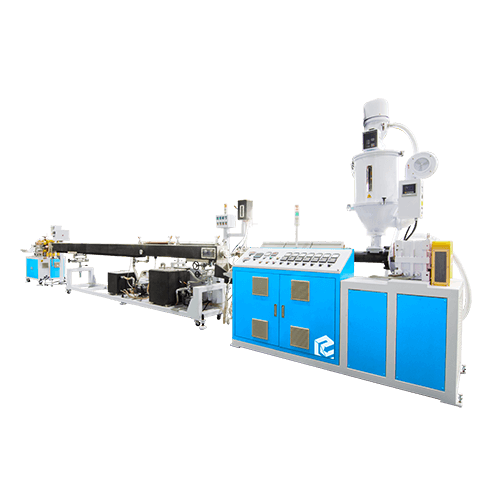

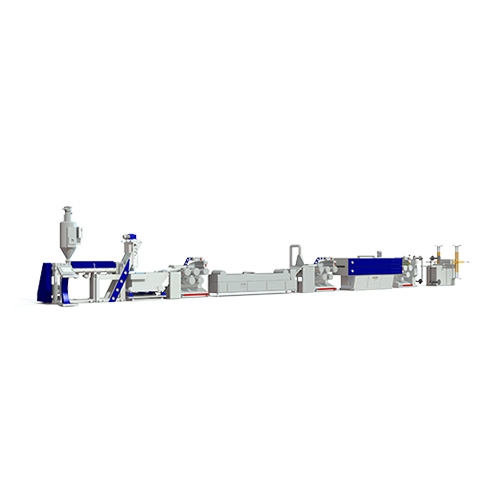

Pipe Extrusion Machine Line

Categories : Extrusion Lines For Pipes and Profiles

Everplast's pipe extrusion machine lines use materials such as PVC, HDPE, LDPE, PE, PP, ABS, PS, PC, and PMMA to extrude products according to market needs and the characteristics of the plastic materials. Everplast's pipe production lines are widely used in construction, industry, agriculture, and other fields. Among them, in construction, it is mainly used for water supply, drainage, power pipelines, etc.; in industry, it is used in chemical pipelines, industrial discharge pipelines, etc.; in agriculture, it is used in irrigation pipelines, water conservancy projects, etc.

HF-FTO 3 In 1 Series:3 in 1 Pelletizing Extrusion / Extruder Pelletizer

Categories : Plastic Pelletizer Machines

Produced by experienced plastic recycling extruder machine manufacturer. Suitable for handling differences of materials. Suitable for processing most of the thermoplastic materials. Applicable materials Film or Flakes : PE、LDPE、LLDPE、HDPE、PP、PET、PS、PA、BOPP、ABS

HF-TS SERIES: Plastic Pellet Extruder ( Twin Screw )

Categories : Compounding Lines

This pelletizing equipment (Twin screw pelletizing extrusion) is mainly applied to the thermal polymer compounding field, and we offer customized compounding solutions for any requests. We supply the twin screw compound process with an appropriate dosing system in order to create a high quality output, and we can design a production line to meet the needs of customers based on the differences of materials. Applicable materials : PET、PA、PS、ABS、PEEK、PE、LLDPE、LDPE、HDPE、 PP、BOPP、TPU、TPE、TPV、TPR、RUBBER、FEP、SMA

ABA Double Die Blown Film Extruders

Categories : Extrusion Dies / Dies Heads

The main characteristics of these kind of Extruder is available to use two or more materials to manufacture film. HSIN LONG supply customized machine specifications for different output, material, film width, film thickness. Further, it reduces the waste of material cost since it allows to add CaCo3, recycled material and color masterbatch in the middle layer for different using.

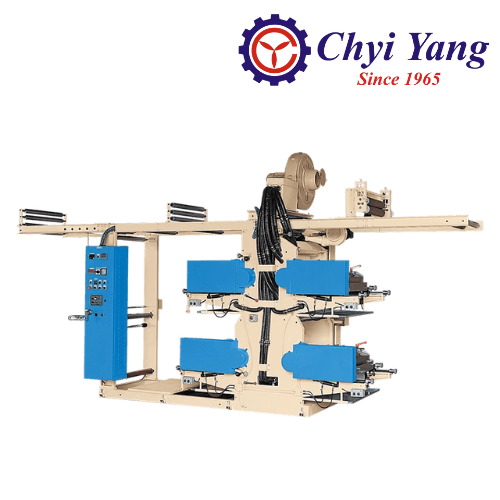

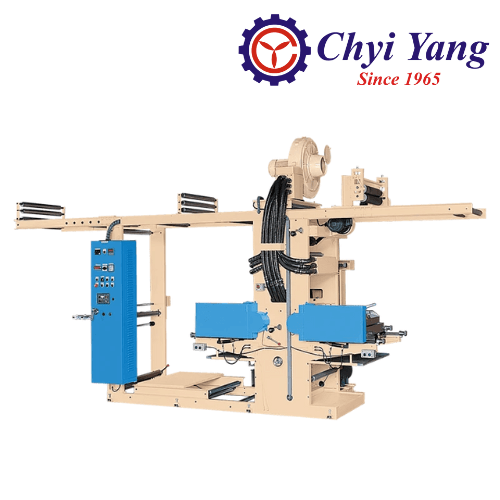

4 COLORS FLEXO PRINTING MACHINE (IN-LINE TYPE)

Categories : Flexographic Printing Machines

These flexographic printers are able to print in four colors, in line with extruder machine. Printing possibility: 0+4, 1+3, 2+2 Max. printing speed 100 mts/min Standard printing length is max. 1200 mm, bigger printing length can be requested as your demand We didn’t show all our models, please don’t hesitate to contact us for bigger printing machines.

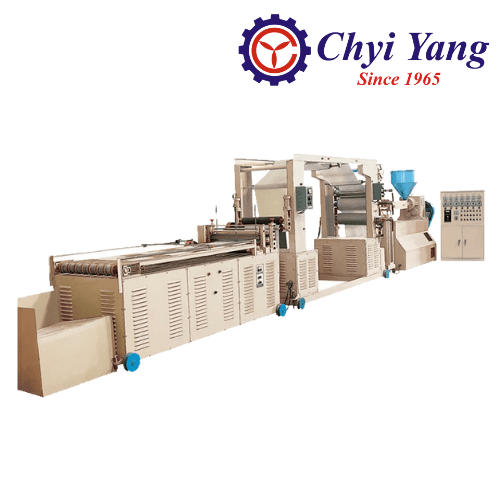

PE FOAM & PE/PP SHEET EXTRUSION LINE

Categories : Foam Extruders

T-Die Extruder machine is equipped with cutter or winder to produce PP/PE sheets PP sheet is available in file cover, stationary etc. Film thickness 0.5~2.5 mm For different machines’ structure, can produce PE, PP sheet & PE foam sheet. We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

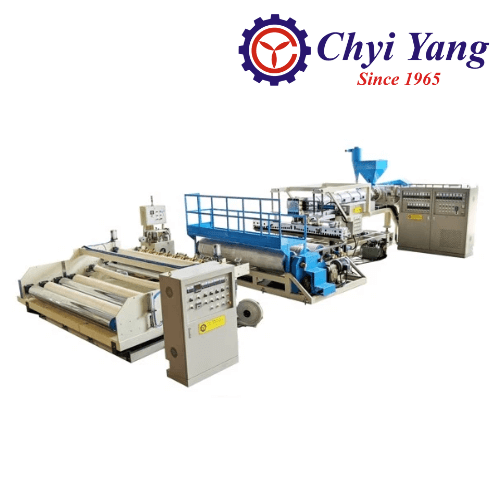

PE STRETCH CASTING FILM EXTRUSION MACHINE

Categories : Film and Sheet Extrusion Lines

T-Die Extruder machine can produce waterproof PE film for baby diaper, sanitary napkin, folders, table cloths, medical film, etc. Film thickness 0.03~1 mm Equipped with a fully automatic winder with cutting and changing rolls functions Hydraulic screen changer for short maintenance stop We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

Plastic Machine Controllers - AR Series

Categories : Industrial Software

The integrated innovative wise technology with reliable Distributed Control System contains higher performance. Software combined with State-of-art window screen to provide smart and instinct object-oriented editing style hybrid switching with simple and popular PLC ladder program editor. His high-speed Ethernet communication network link-up between Humanity Interface and remote devices to displaying the future one-stop control advantages! It can be broadly applied to automated machinery control, such as injection molding extruder machine controllers and equipment. Arico

2 COLORS FLEXO PRINTING MACHINE (IN-LINE TYPE)

Categories : Flexographic Printing Machines

These flexographic printers are able to print in two colors, in line with extruder machine. Printing possibility: 0+2, 1+1 Max. printing speed 100 mts/min Standard printing length is max. 1200 mm, bigger printing length can be requested as your demand. We didn’t show all our models, please don’t hesitate to contact us for bigger printing machines.

HDPE/PP Monofilament Extrusion Line (JC-MNP Series)

Categories : Extrusion Lines For Filaments and Yarn

JC-MNP series monofilament extrusion line designed with single-stage-drawing and heat setting. The line is specially conceived to process polypropylene (PP) and high density polyethylene (HDPE).

Bristle Monofilament Extrusion Line (JC-MNB Series)

Categories : Extrusion Lines For Filaments and Yarn

JC-MNB series monofilament extrusion line designed exclusively for the manufacturing of virgin and/or recycled polyester (PET) and polypropylene (PP) for broom and brush application.

Danline Monofilament Extrusion Line (JC-MND Series)

Categories : Extrusion Lines For Filaments and Yarn

JC-MNP series Danline Monofilament Line designed with double-stage-drawing and heat setting. The line is specially conceived to process high tensile strength monofilament for varies industrial applications.

PA/PET Monofilament Extrusion Line(JC-MNN Series)

Categories : Extrusion Lines For Filaments and Yarn

JC-MNN series monofilament extruding line designed with two-stage-drawing and additional heat setting. The line is specially conceived to process polyamide (PA6, 6.6), polyester (PET), and polypropylene (PP).

Tape Extrusion Line (JC-FY Series)

Categories : Tape Extrusion Machines

The JC-FY series flat tape yarn extrusion line is available in 85mm and 120mm screw extruder, designed to produce tape line for various applcations, an ultimate solution offering combination of efficiency, reliability, performance, and premium quality tape product.

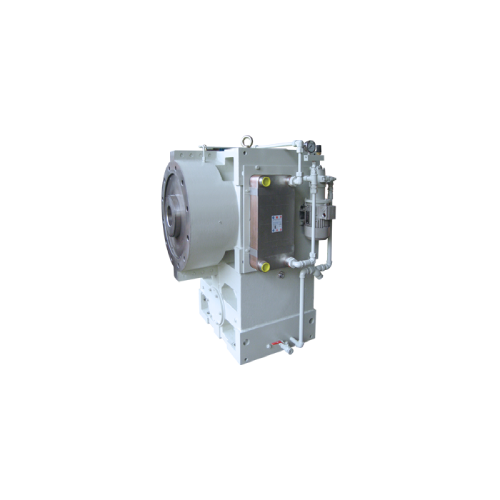

Twin Screw Extruder - Counter Rotating Type

Categories : Gearboxes

(1) Both Co Rotating & Counter Rotating types of TB series Twin Screw Gear Reducer are composed by Input & Output elements. Especially for output side which installed by Thrust Bearing plus with flange which could suffer high pressure to absorb the axial pressure caused by the extruders. (2) Following AGMA criterion to design gear elements which adopts low-carbon alloy steel bar materials(Normally, it is SCM420 or same level). The precision reaches AGMA 10 level after carburization heat treatment then treating gear surface grinding to make sure low noise, low abrasion and high efficiency during operation. (3) #294 Series Thrust bearing with axial self-aligning roller type & muti-row stacked tandem bearing package to have advantage of low friction heavy axial load capacity.

Eco-Friendly Plastics Recycling Extruder Series Water Cooling

• Model: TY-LW Series • Country of Origin: Taiwan • Applicable resin: PP, PE, ABS, PS, HIPS. • Specific resin: POM, PC, ACRYLIC

for Extruder Machine - Single Screw Tex Series

Categories : Gearboxes

CASE Material: FC 25 module cast iron GEAR SHAFT a. Material : SNCM220.Carburization & Hardness HRc56∘~60∘ b. Gear precision: reach JIS 2 level GEAR Material: SCM420 Carburization & Hardness HRc56 ∘ ~58∘ b. Gear precision: reach JIS 2 level OUTPUT SHAFT Material: SCM440 Hardness: reach HRc28 ∘ ~32∘ High Frequency Heat Treatment in HRC 48〫-52〫 in the connected area of Oil Seal Bearing Brand : SKF 、FAG、NSK (OPTION), Oil Seal : NOK or SKF Brand, material: Viton Lubrication System : OIL BATH SPLASH TYPE Forced type (Elements including as below) Motor PUMP(1HP/220/380V+Rop210HA) Teco Brand Cooling device(plate type) or Cylinder type Y Type Filter Temperature Gauge Pressure Gauge Pressure Switch Gear Measuring Report : Lead/Profile/Pitch testing Report Operation temperature rising: below +40 ℃ (Ambient temperature) Operation Vibration < 2.3mm/sec Operation Sound < 80Db, None Oil Leakage

High Filler Modified Compound Making Line (CaCo3, TiO2 or Talc)

Categories : Compounding Lines

High Filler Modified Compound Making Line (CaCo3, TiO2 or Talc) Our High Filler Modified Compound Making Line uses our extruder machinery to process different types of compound materials into pellets. Our simple to operate line, comprises of a dispersion kneader and extruder to meet all of your specific compound making needs. (HDPE, Recycled HDPE, Ti02, Talc, PP+CaCo3 etc) We can also provide automated production line for you, and to adjust and customize equipment according to your needs.